Context-Aware Fault Diagnosis

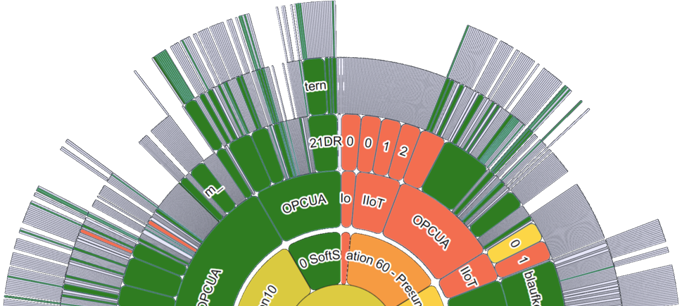

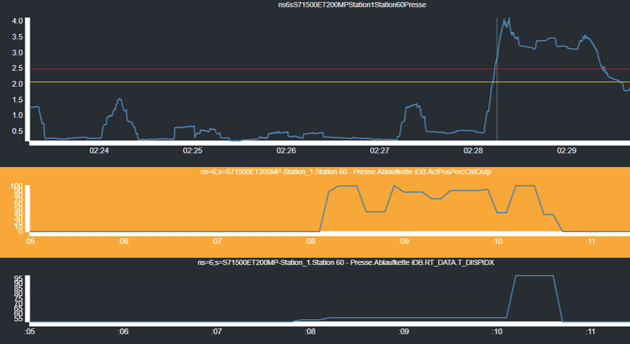

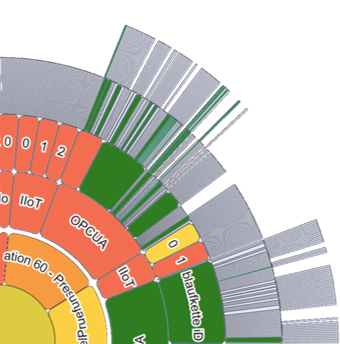

A fault diagnosis application becomes context‑aware when the current production situation is used in the reasoning process. After years of research, we propose CPSlytics, the first context‑aware fault diagnosis system for Industry 4.0 environments. Equipped with the latest unsupervised AI technology, CPSlytics observe and reason software and hardware modules to pinpoint towards the origin of the fault. Mitigating complexity for your professionals to minimize the downtime.